Summer is approaching, and when girls go out shopping and playing, they like to create a beautiful makeup, which will make them feel happier.

But when summer comes, high temperatures and ultraviolet rays from the sun can easily cause the skin to sweat and become oily, and makeup is not long-lasting. Girls need to reapply makeup frequently, which is very troublesome and makes girls feel anxious. As one of the important parts of setting makeup, using setting powder can effectively set makeup, absorb oil, and brighten skin tone. It is essential for girls who want to have fairer skin.

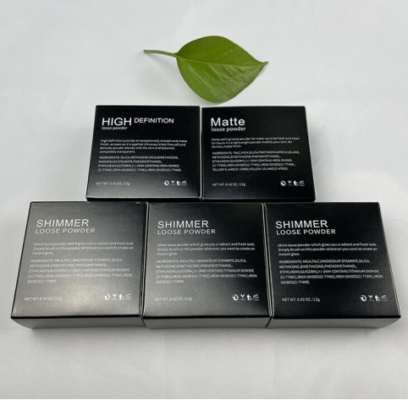

Let’s talk about the types of loose powder

Loose powder is generally divided into two types: colored loose powder and colorless loose powder. Among them, colored loose powder is used to adjust skin tone and even out skin, while colorless loose powder is used to set makeup and absorb oil. Generally speaking, loose powder ingredients include powder (such as silica gel, hydrophilic powder, etc.), moisturizing ingredients (such as sodium hyaluronate), makeup setting ingredients (such as hyaluronic acid), etc. Girls can use loose powder to control facial shine, make makeup last longer, and make skin tone more even.

When you buy loose powder, you should choose it according to your skin characteristics. For example, dry skin is suitable for loose powder containing moisturizing ingredients. Colored loose powder should be used with a color that is similar to the skin color or can modify the skin color. Choose the makeup effect, gloss, etc. according to your personal needs. . If your skin is more sensitive, you should choose loose powder without irritating ingredients, which may be more suitable for you.

General manufacturing process of loose powder

1.Loose powder manufacturers prepare loose powder formulas, such as the types/proportions of raw materials, and strictly select raw material suppliers, requiring strict chemical testing.

2.Loose powder manufacturers need to purchase loose powder raw materials as planned, including powder, moisturizing, makeup setting ingredients, and color pigments. The upstream suppliers of loose powder raw materials are stable and enjoy reputation, which can avoid any commercial risks from the source.

3.The loose powder manufacturer uses mixing equipment to mix the raw materials evenly and thoroughly according to the formula proportion.

4.In order to ensure fine color and texture, loose powder manufacturers must grind the mixed raw materials through a grinder.

5.In order to make the particle size of loose powder uniform, loose powder manufacturers need to crush and sieve the ground raw materials.

6.Afterwards, the manufacturer needs to dry the loose powder to remove moisture and increase the shelf life. Manufacturers need to put the processed loose powder into a drying room or baking equipment for drying processing to complete the initial production of loose powder products.

7.After the production of loose powder is completed, the next step for the manufacturer is the filling process. Fill the manufactured loose powder into the designated powder box or powder can, and then seal and package it.

8.Before launching on the market, manufacturers will conduct strict quality inspections on loose powder, including appearance inspection, texture testing, formula confirmation, etc., to ultimately create loose powder products with stable quality, uniform color, and comfortable use.

Why Choose Private Label Loose Powder Manufacturer?

If the brand owner invests in building a factory to manufacture loose powder, it will bring many risks and involve too much capital investment. Compared with the brand itself, it is much better to have loose powder manufactured by a third-party private label manufacturer. Let me tell you why.

1.Private label manufacturing costs are lower

As we all know, if you have a start-up capital, the cost of investing in and building a factory is very high. You not only have to consider the rent and factory construction costs, but also the increasing labor costs, R&D expenses, patent purchases, and also face greater business risk.

Therefore, in fact, the vast majority of cosmetic brands in the world cooperate with private label manufacturers, because they are often good at the manufacturing industry. Because of their professionalism and continuous exploration in this field, the production equipment and infrastructure are already quite complete, and the production volume is getting higher.

Their production efficiency is higher than other manufacturers, and they can control costs to a minimum, so that they can produce lower-cost loose powder for the brand, which will help the brand’s market pricing to be more advantageous.

2.Private label manufacturers have accumulated a lot of expertise

Much like other industries, the accumulation of expertise and patents often takes many years. The same is true for the cosmetics manufacturing industry. Without many years of experience and investment, it is often difficult for factories to accumulate sufficiently advanced manufacturing technology.

Generally speaking, private cosmetics brand manufacturers usually have accumulated many years of experience in this field, accumulated a considerable number of technical patents, raw material formulas, professional technical personnel, etc., to provide a higher level of production technology and ensure stable product quality.

Link:https://leecosmetic.com/product/new-arrivals-long-lasting-oil-control-makeup-loose-powder/

3.Production plans can be adjusted more flexibly

Today’s society is developing at a fast pace, which means that market demand is constantly changing. The loose powder market may also be affected by social media/popular trends, which means that manufacturers are required to be able to flexibly adjust production plans. If you invest in setting up a factory, you may not be able to Production capacity limitations. The inability to flexibly adjust leads to shortage of supply in peak seasons or inventory backlog in off-seasons.

By entrusting third-party private brand loose powder manufacturers, it is completely different. Because they have different production lines and a large number of engineers and technicians, they can adjust plans more quickly according to customer needs.

4.Disperse the brand’s production and supply chain risks

By entrusting the manufacturing process to a private label loose powder manufacturer, you can spread the production and supply chain risks, making your business more stable.

At the same time, overall, such a business model reduces your own operating risks, especially when facing market fluctuations, or when entering a new market with uncertain demand.

5.Asset-light operations make brand operations more effective

Leaving the manufacturing to a professional private label loose powder manufacturer can make brand operations more effective. You only need to focus on core businesses such as marketing and brand building, and do not need to spend a lot of energy managing manufacturing plants and improving the overall competitiveness of the company.

Private Label Loose Powder Manufacturer

You can consider cooperating with Leecosmetic, a well-known cosmetics foundry in China. You only need to provide your needs and tell the characteristics of your target customers, and then Leecosmetic’s marketing team will provide you with a plan, provide free sample testing, and provide high-quality loose powder products that meets market demand. Company profile:https://leecosmetic.com/about-leecosmetic/

Leecosmetic has more than 30 years of cosmetics manufacturing experience and has already passed ISO and GMP certification. It has an experienced professional team specializing in the production of high-quality cosmetic products. Its services include product development, packaging design, production and quality control. Welcome to contact us for further communication. Contact us:https://leecosmetic.com/contact-us/

links:

Why is packaging design important ? Find your tube & powder products’ packaging solutions here